Leading Manufacturer & Exporter

Premium Asphalt Batch Mix Plants – Manufactured in India with European Technology

Vinayak Equipment is a global manufacturer, supplier, and exporter of Asphalt Batch Mix Plants. We specialise in modern, fuel-efficient, and CE-certified road construction machines that are used in highways, airports, urban roads, and large-scale infrastructure works, with 100% client satisfaction.

India's Trusted Asphalt Batch Mix Plant Manufacturer | Exporter Worldwide

We manufacture a product range comprising Stationary Asphalt Batch Mix Plants, Mobile Asphalt Batch Mix Plants, Portable Asphalt Batch Mix Plants, and Compact Asphalt Batch Mix Plants, individually designed to be highly efficient, accurate, and long-lasting. Vinayak Construction Equipment is a top-rated Asphalt Batch Mix Plant Manufacturer in India, offering the complete range of performance batch mix plants for the production of high-quality asphalt. Our asphalt batch plants, powered by the latest technology and sturdy structural design, are capable of uniform mixing, energy-saving, and less maintenance; thus, they are the perfect choice for highways, airports, and large-scale road projects. Being equipped with rich experience for several decades and having a strong international presence, Vinayak Construction Equipment can be termed as a brand that combines quality and innovation in asphalt mixing solutions.

This dedication to quality, innovation has seen us become the contractor of choice in government projects, contractors, and other private developers around the world.

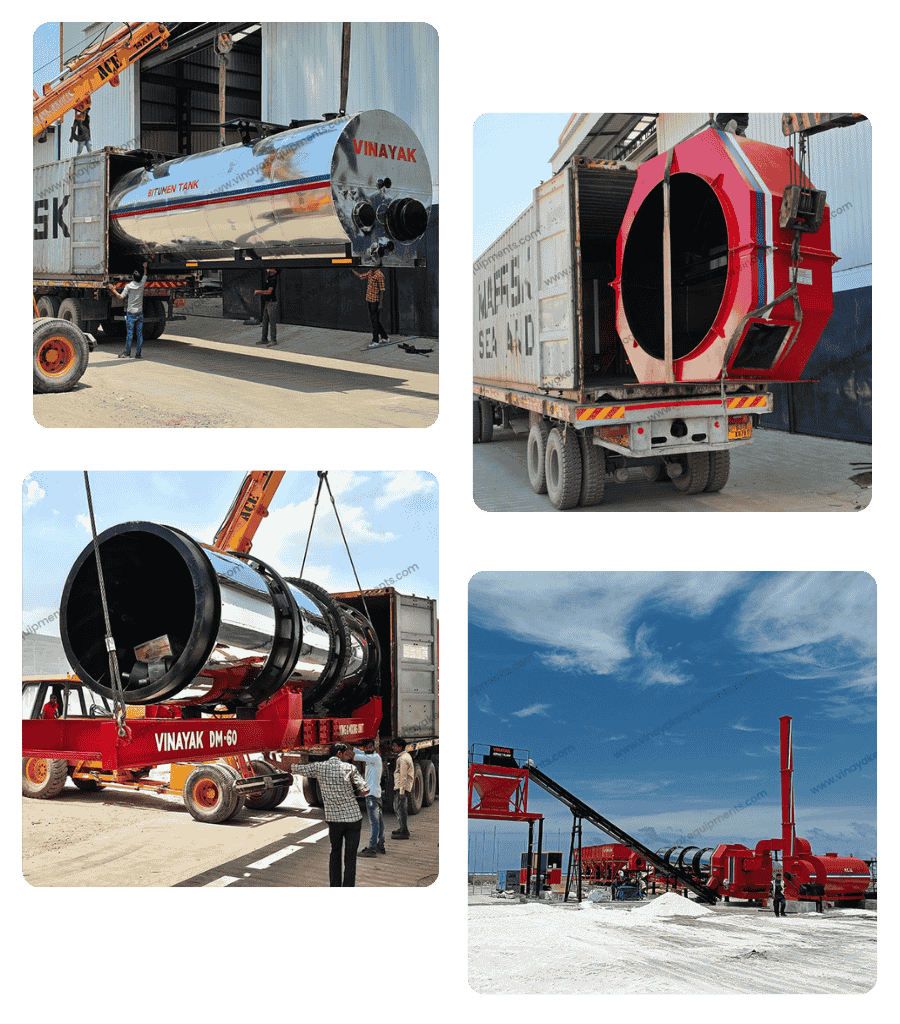

Our Journey - From Vision to Global Reach

Established with the aim of providing the best road construction machinery, Vinayak Equipment has expanded to become a asphalt batch mix plant manufacturer, supplier well-known brand in the world. Over the years, we have:

- Developed asphalt plants that are efficient in fuel consumption, friendly to the environment, and high-performance.

- Planted hundreds of plants in India, Africa, the Middle East, and other.

- International quality standards, which are ISO 9001:2015 and CE certifications received.

- Distributed best-after-sales service, education, and technical assistance.

We are dedicated to advancing road construction technology, reducing environmental impact, and maximizing the ROI for contractors.

Why Vinayak Equipment Leads Asphalt Plant Manufacturing in India

Experience & Expertise

Our engineers have over 23 years of road construction machinery, and they know what is needed in modern asphalt production. We provide tailored solutions to satisfy project requirements regardless of the size of the project, whether urban road projects, highways, or airports.

Innovation & Technology

We have highly developed hot mix asphalt technology, automated control, and pollution control units in our plants. The incorporation of the state of the art technology is used to maintain the uniform quality of asphalt, minimize fuel usage, and streamline operations.

Global Presence

Vinayak Equipment has sold plants to 35 or more countries, such as Africa, the Middle East, and Southeast Asia. We have become a worldwide supplier of choice due to our quality shipping, installation, as well as technical support.

ISO & CE Certification

Our asphalt plants and equipment are all certified to ISO 9001:2015 and CE to international standards of quality, safety, and performance.

Comprehensive Support

We offer end-to-end services such as surveying of a site, plant installation, training, spare parts provision, and maintenance. This makes sure that all clients have continuous and efficient operations.

Capacities

From 40-160 TPH for Every Project

All our products are designed to provide durability, high efficiency, and cost savings, making Vinayak Equipment a reliable brand in the asphalt plant industry.

Our Mission & Vision

Mission

To offer cost-effective, environmentally friendly, and innovative asphalt plant solutions.

Vision

To be the most relied-upon global brand in road construction equipment.

Values

Customer Satisfaction, Innovation, Sustainability, and Quality.

World Class Engineering

Asphalt and Road Concrete

Equipment Manufacturer

Global Clientele & Projects

Vinayak Equipment has a wide variety of customers, including:

- Government road construction departments.

- Privatized infrastructure developers.

- International contractors

Our plants have been utilized in highways, expressways, airports, and urban roads projects, and have supplied quality asphalt to give long-lasting roads.

Quality assurance

Quality is at the heart of everything we do. Our Asphalt Batch Mix Plants are produced with the implementation of tough quality control measures, which implies that all parts have impeccable quality, durability, safety, and performance. Whether it is the sourcing of materials or performing the final inspection, all the stages in between are strictly tested and closely checked. This attention to quality means that there is constant output every time.

Why Vinayak Equipment Stands Out

- Eco-friendly and fuel-efficient plants

- Easy-to-use control systems.

- Long-lasting and low-maintenance designs.

- All project sizes have flexible plant capacities

- Trusted technical support and availability of spare parts

Latest Updates on Asphalt Plant Innovations

Stationary Asphalt Batch Mix Plant

Get the Best Stationary Asphalt Plant Supplier & Manufacturer for Your Road Project Needs Consistency and quality of asphalt mix

Asphalt Batch Mix Plant vs Asphalt Drum Mix Plant – Which One Is More Suitable for Your Project?

Asphalt Batch Mix Plant vs Drum Mix Plant | Which is Right for Your Project? Among road construction machines, the